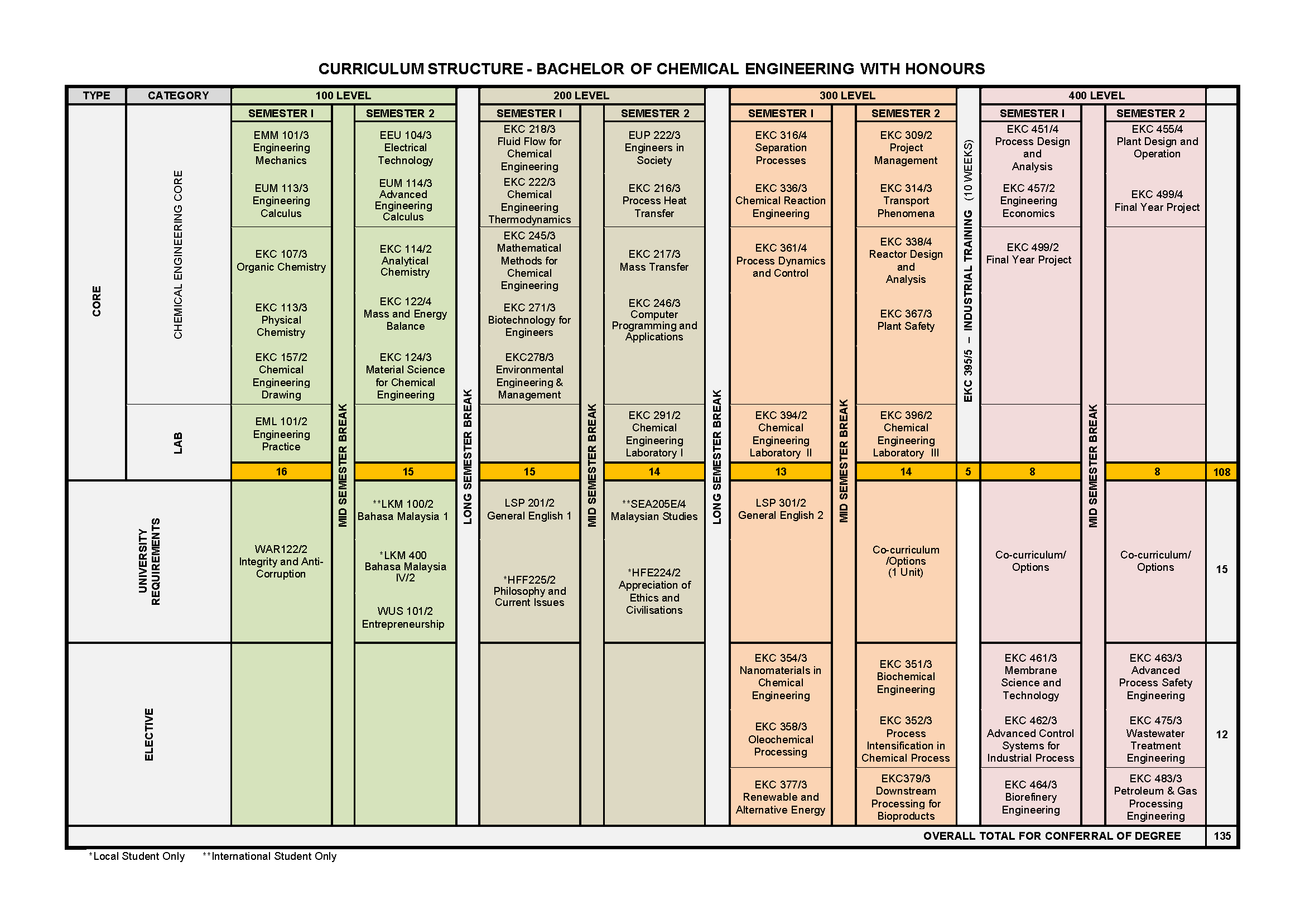

Curriculum Structure & Syllabus

First Year

| EMM 101/3 Engineering Mechanics | |

|

Synopsis: |

This course is an introduction to the mechanics of rigid bodies. It is divided into two areas: Statics and Dynamics. In Statics, the student will learn the fundamental concepts and principles of rigid bodies in static equilibrium. In Dynamics, the student will learn the fundamental concepts and principles of the accelerated motion of a body (a particle). Consideration is given on the fundamental of mechanics and structure analysis, including concepts of free body diagram as well as force, moment, couples, kinematic of motion, momentum, impulse, conservation of energy and equilibrium analyses in two and three dimensions. |

| EUM 113/3 Engineering Calculus | |

| Synopsis: |

This course reviews the topics on calculus of one and multivariable. It also covers the topics of solutions of ordinary differential using analytical and numerical methods. |

| EKC 107/3 Organic Chemistry | |

| Synopsis: |

This course deals with important industrial organic chemical processes and chemical reactions. Typical reactions like hydrogenation, esterification/transesterification, Friedel-Crafts reaction and polymerization will be described with emphasis on compounds and reactions of industrial importance. Flow charts of specified processes will be introduced and discussed. Some experiments will be carried out which focus on synthesis of basic organic chemical products to reinforce the theory |

| EBB 113/3 Engineering Materials | |

| Synopsis: |

The course is an introductory course on engineering materials which is divided into three main parts. The first part includes the classifications of materials that determine their applicability, the structure of the materials explained by the quantum-mechanical principle that relates electrons to energies, bonding scheme of different materials, the structure of crystalline solids and introduction to imperfection in solids. The second part covers the mechanical characteristics of materials for service use and methods of assessing the mechanical characteristics of materials. The second part also includes the behaviour of material in thermal equilibrium (free energy concept, phase transformation and examples of phase diagrams), diffusion mechanisms and usual causes of failure in a given material. The third part is on application and processing of specific material (metals, ceramics and polymer). Introduction of electrical, magnetic and optical properties of materials is also presented in the course. In general, this introductory materials science and engineering course deals with the different material types (i.e., metals, ceramics, polymers, composites), as well as the various kinds of properties exhibited by these materials (i.e., mechanical, electrical, magnetic, etc.) which intended to equip the students with necessary knowledge on material science and engineering. |

| EKC 107/3 Organic Chemistry | |

| Synopsis: |

This course deals with important organic chemical processes and industrial chemical reactions. Typical reactions like hydrogenation, esterification/transesterification, oxidation and polymerization will be described with emphasis on compounds and reactions of industrial importance. Some experiments will be carried out which focus on synthesis of basic organic chemical products to reinforce the theory. |

| EKC 157/2 Chemical Engineering Drawing | |

| Synopsis: |

The student will be exposed to the basic concepts of standard Engineering Drawing and the application of conventional signs, symbols, lettering, geometry, instrument needed, types of orthographic and isometric presentation including piping system. It also exposes students to application of AUTOCAD and PROCEDE software in engineering process drawing. |

| EML 101/2 Engineering Practice | |

| Synopsis:

|

Trainings are based on theoretical and practical concepts which consists of manufacturing process; computer numerical control (CNC), lathe, mill and thread machining, joint process, arc welding, gas welding and MIG welding, metrology measurement, electric and electronic circuits, and safety practice in laboratory and workshop. |

| EEU104/3 Electrical Technology | |

| Synopsis: |

This course introduces students to the fundamental concepts and electrical elements. This course covers direct current (DC) circuit analysis, alternating current (AC) one-phase circuit analysis, AC three-phase circuit analysis and electromagnetic circuits. |

| EUM 114/3 Advanced Engineering Calculus | |

| Synopsis: |

This course covers the topics on linear algebra, Fourier series, partial differential equations, and vector calculus. Numerical techniques for solving systems of linear equations and partial differential equations are also given. |

| EKC 114/2 Analytical Chemistry |

|

| Synopsis: |

This course introduces the fundamentals of qualitative and quantitative measurements with emphasis on spectrometry, common analytical equipment like UV/Vis, GC, HPLC and AAS. Laboratory demonstrations on the analytical equipment will also be conducted. |

| EKC 122/4 Mass and Energy Balances | |

| Synopsis: |

This course is an introduction to the analysis of chemical processes with an emphasis on mass and energy balances. Topics include an introduction to flow chart for the chemical industry, concepts of recycle, bypass and purge in mass balances for reactive and non-reactive systems. Students will also be introduced to the forms of energy, tables of thermodynamics, concept of latent heats and energy balance for non-reactive and reactive processes. MS Excel is used to solve mass and energy balances problems in chemical processes. |

| EKC 124/3 Material Science for Chemical Engineering | |

| Synopsis: |

The course is an introductory course on materials for chemical engineering. The first part of this course covers the engineering materials classifications that determine their applicability, the structure of the materials and its relation towards forces and stresses. It also includes the structure of crystalline solids, imperfection in solids and diffusion mechanism. The second part covers the behaviours and characteristics of engineering materials including mechanical properties, corrosion/oxidation of materials and its prevention. |

Second Year

| EKC 218/3 Fluid Flow for Chemical Engineering | |

| Synopsis: |

This course covers the basic principles of fluid transport including the phenomena of fluid and theories related to fluid static, incompressible fluid and compressible fluid. The student will also be exposed to mass and energy balances of fluid flow in conduits, transportation/metering of fluids, fluidization, flow past immersed bodies, agitation and mixing of liquids. |

| EKC 222/3 Chemical Engineering Thermodynamics | |

| Synopsis: |

This course introduces the concepts of chemical engineering thermodynamics including laws of thermodynamics, volumetric and thermodynamic properties of fluids, thermodynamics properties of fluids, thermodynamics applications, refrigeration and liquefaction, solution thermodynamics. |

| EKC 245/3 Mathematical Methods for Chemical Engineering | |

| Synopsis: |

This course will provide the knowledge of various numerical techniques in solving chemical engineering problems. Students will be introduced to error analysis, optimization techniques and numerical methods to solve Ordinary and Partial Differential Equations. Application of MATLAB and Microsoft Excel for solving numerical problems. |

| EKC 271/3 Biotechnology for Engineers | |

| Synopsis: |

This course provides an overview of fundamental concepts in Biotechnology which are pertinent to Engineering and technology. Primary topics include: Cell, cell metabolic pathways, microbial growth kinetics both batch and continuous system, sterilization and enzyme kinetics. |

| EKC 278/3 Environmental Engineering and Management | |

| Synopsis: |

This course imparting knowledge on ISO 14001, product life cycle assessment (LCA), 3R (reduce, reuse, recycle) concept, waste minimization, sustainability, green technology, EIA documentation as well as Legislation and Environmental act of Malaysia & International. Topic on wastewater includes source of wastewater, wastewater characteristic, impact of water pollution and wastewater treatment. Topic on air pollution covers pollutants effects, pollutants criteria, air pollution meteorology, pollutant prediction, pollutant control sources and operation of air pollution control equipment. Topic under solid waste covers logistics of waste, landfill and of waste generation prevention. Topic under hazardous waste covers classification, properties, regulations, treatment and disposal technologies. |

| EUP 222/3 Engineers in Society | |

| Synopsis: |

This course provides exposure to students the fundamentals principles of engineering ethics such as code of engineering ethics and the responsibility of a professional engineer, basic law covering introduction to Malaysian Laws, engineering accounts and basic introduction to management theory. |

| EKC 216/3 Process Heat Transfer | |

| Synopsis: |

This course involves heat transfer topics such as conduction, convection, radiation, condensation, boiling and heat exchanger design. The course will emphasize on the principles of heat transfer in steady and unsteady state by conduction, convection and radiation. The course will also focus on the application of heat transfer to the design of heat exchanger and its working principles. Students will also be exposed to problem-solving procedures in heat transfer applications and in heat exchanger design. |

| EKC 217/3 Mass Transfer | |

| Synopsis: |

Students are introduced to the theories of diffusion and mass transfer. Basic principles of unit operations such as distillation, absorption and extraction are covered. |

| EKC 246/3 Computer Programming and Applications | |

| Synopsis: |

The course introduces the use of MATLAB in problem solving in engineering with a special emphasis on basic calculations in chemical engineering. It covers arrays, which are the basic building blocks in MATLAB; file usage, built in math functions, and user defined functions; programming using branch and loop constructs; 2-D and 3-D plots, and fitting data to models. Other tools such as Microsoft Excel will be used as well as MATLAB for solving linear and nonlinear equations and function optimization. This course will also provide student with the knowledge of process simulation in chemical engineering design using software. This course also guides students through the key steps in process simulation modelling for chemical processes in which the students will gain hands-on experience on the techniques to troubleshoot common simulation problems. |

| EKC 291/2 Chemical Engineering Laboratory I | |

| Synopsis: |

This course involves the application of chemical engineering principles related to Fluid Flow, Heat Transfer, Thermodynamic and Mass Transfer through executing 19 Pilot Plant experiments in the Unit Operation Laboratory. Each student will be exposed to at least 9 experiments and learn to prepare laboratory report as well as present the solution during Viva Voce. |

Third Year

| EKC 316/4 Separation Processes | |

| Synopsis: |

To introduce the basic and advanced concepts of separation processes to the students. This includes mass transfer and the design criteria of processes such as humidification, drying, crystallization, adsorption, filtration and membrane processes, supercritical fluid extraction and advanced distillation. |

| EKC 336/3 Chemical Reaction Engineering | |

| Synopsis: |

This course contains knowledge on the principles of homogeneous reaction kinetics, reaction equilibria, isothermal and non-isothermal, ideal, non-ideal, adiabatic, non-adiabatic reactor design. |

| EKC 361/4 Process Dynamics and Control | |

| Synopsis: |

This course provides the knowledge of process dynamics and control in chemical engineering processes. It covers the concept of theoretical model, dynamic behaviour of open and closed-loop systems, basic type of controllers, PID controller tuning procedures and controller stability criterion. This course also introduces enhanced single loop control strategies and basic process instrumentation. |

| EKC 394/2 Chemical Engineering Laboratory II | |

| Synopsis: |

This course would be an application of heat transfer, mass transfer and combined heat and mass transfer through executing experiments in Unit Operation Laboratory. Each student will be exposed to at least 5 experiments (1 Open Ended Laboratory (OEL) and 4 Traditional Laboratory (TL)) and learn to prepare comprehensive laboratory report for OEL and TL as well as present the solution during Viva Voce. |

| EKC 309/2 Project Management | |

| Synopsis: |

This course introduces some fundamental principles of engineering project management and the execution of a systematic and organized project. Students will learn in-depth the role of project manager as well as a team member of a project execution group, while building the skills to plan, construct scheduling, carry out monitoring and evaluation of the engineering project. |

| EKC 314/3 Transport Phenomena | |

| Synopsis: |

The course contributes primarily to the student’s knowledge of transport processes in chemical engineering by providing molecular level understanding of transport processes and establishing the modelling tools (mathematics and physics) to predict macroscopic behaviour of real systems. This course develops the skills and tools needed for engineering practice, especially for extension of new models to new systems. The course describes the underlying physical processes involved in transport of momentum, heat and mass. This information supports the empirical models for transport parameters widely used in many unit operations analyses. |

| EKC 338/4 Reactor Design and Analysis | |

| Synopsis: |

The student will be exposed to design conventional catalytic, multiphase reactors and bioreactors. Sufficient knowledge on the preparation and characterization of different types of catalysts needed for industrial processes will also be given. |

| EKC 367/3 Plant Safety | |

| Synopsis: |

This course provides the principles knowledge related to safety in chemical and process industries. It covers to the introduction of safety concept, industrial hygiene, characteristic of major hazards, derivation of mathematical model related to leakages and dispersion. Students will be also taught hazard identification and risk assessment techniques. Finally, the use of safety concept in designing chemical plant to produce Inherently Safer Plant. |

| EKC 396/2 Chemical Engineering Laboratory III | |

| Synopsis: |

This course covers experiments on chemical reactions, mass transfer, heat transfer, separation processes, process control and environmental treatment. Each student will be exposed to at least 5 experiments (1 OEL and 4 TL) and learn to prepare comprehensive laboratory report for OEL and TL as well as present the solution during Viva Voce. |

| EKC 354/3 Nanomaterials in Chemical Engineering | |

| Synopsis: |

This course focuses on the fundamental aspect of nanoparticle interactions and interfacial phenomena. Fundamental colloidal interactions, including (i) van der Waals and (ii) electrical double layer interactions will be discussed in detail. The balance of these two interactions leading to stability of nanoparticle suspension will also be discussed. The self-assembly concept will be explained by using micellisation as a modelled system. The formation of hybrid nanoparticles-polymer materials will be given to familiarize the students with the applied aspect of nanomaterials with multiple functionalities. The application will focus on nanomaterials for chemical processes in the environmental and biomedical engineering. |

| EKC 358/3 Oleochemical Processing | |

| Synopsis: |

This course gives an introduction to the oleochemical industry operation. It covers some introduction to oils and fats compositions, vegetable oil/plant mill operations, plant oil refinery process, production of edible products, fatty acid and soap production, as well as biofuel derived from vegetable oil and fats. Various fats and oil analyses will be discussed. Various other oleochemical reactions, process sustainability, environment impact and waste management will be discussed based on specific applications. |

| EKC 377/3 Renewable and Alternative Energies | |

| Synopsis: |

This course will cover with the issues of renewable energy and alternative energy sources. The sustainable energy will include biomass utilization and conversion technologies, solar energy generation including energy collection, storage, and its applications, Photovoltaic, wind farms and collection devices. The alternative energy will include fuel cell performances, types of fuel cells, fuel cell systems, basic thermodynamics and heat/mass transfer in fuel cell systems, biofuel production from bioresources; hydrogen-based technologies including storage of hydrogen. The course will analyse in terms of cost benefit, energy solutions and cost comparison. The analysis will be project based and will provide solution in terms of nature of energy, its resources, energy conservation and efficiency. The economic and environmental effects of energy use will be included. |

| EKC 351/3 Biochemical Engineering | |

| Synopsis: |

This course covers knowledge about principles of biochemical engineering used in industries, design, operation and control of bioreactors used in bioprocess. Various unit operations employed in bioprocess industries, production of chemicals using fermentation and bioprocesses will also be introduced. |

| EKC 352/3 Process Intensification in Chemical Processes | |

| Synopsis: |

Students are introduced to the concept and technologies of process intensification in chemical processes. It covers the underlying principles of intensification technology and its application in current chemical process industries with an ultimate aim of to build a chemical plant small enough to sit on a table-top with no loss of productivity, economical and inherently safe which will deliver improved product quality, be responsive to market needs and able to create a sustainable environment. |

| EKC 379/3 Downstream Processing for Bioproducts | |

| Synopsis: |

This course gives an overview of possibilities and problems typically associated with the recovery of biochemical and pharmaceutical products. It focuses on the concentration, recovery and isolation of the biological molecules relevant in biochemical and pharmaceutical industries. The principles, advantages and limitations of centrifugation, membranes, cell disruption, two-phase extraction, precipitation crystallization and chromatography are discussed. The integration of bioseparation schemes will be emphasized with specific applications. Good manufacturing practice for producing biological products will be studied. |

| EKC 379/3 Downstream Processing for Bioproducts | |

| Synopsis: |

This course gives an overview of possibilities and problems typically associated with the recovery of biochemical and pharmaceutical products. It focuses on the concentration, recovery and isolation of the biological molecules relevant in biochemical and pharmaceutical industries. The principles, advantages and limitations of centrifugation, membranes, cell disruption, two-phase extraction, precipitation crystallization and chromatography are discussed. The integration of bioseparation schemes will be emphasized with specific applications. Good manufacturing practice for producing biological products will be studied. |

Fourth Year

| EKC 451/4 Process Design and Analysis | |

| Synopsis: |

To introduce the preliminary design of chemical process plant to the students. This includes process creation and analysis, synthesis of separation trains, heat and power integration and process equipment design. ASPEN PLUS II will be implemented throughout the course in the process flow sheeting and equipment design. |

| EKC 457/2 Engineering Economics | |

| Synopsis: |

This course extends from the basic concepts of material and energy balances, fluid flow, heat and mass transfer and reaction engineering needed for preliminary sizing of equipment. Based on the equipment sizing, fixed capital cost will be estimated. The importance of time value of money and others economic analytical tools are then used to estimate the total capital investment as well as manufacturing cost of a chemical process. The feasibility study based on the profitability and sensitivity analysis will lead to the decision making on the plant investment. |

| EKC 499/6 Final Year Project | |

| Synopsis: |

This course provides the platform for carrying out individual research on specific areas in chemical engineering. This project involves literature survey, theoretical analysis, computer modelling and/or design of experiment, also development of experimental setup, data analysis and presentation of results in terms of oral and written report. |

| EKC 455/4 Plant Design and Operation | |

| Synopsis: |

This course covers economics analysis, plant design of piping and instrumentation diagram (P&ID), waste management, life cycle assessment, risk assessment analysis, plant safety, HAZOP, HAZID, operability and reliability and plant optimisation. IT tools that will be introduced are AUTOCAD and Microsoft VISIO for piping and instrumentation diagram (P&ID), ASPEN One for plant dynamics and optimization analysis, GABi for life cycle assessment (LCA) and BREEZE for risk assessment analysis. |

| EKC 461/3 Membrane Science and Technology | |

| Synopsis: |

In this course, the focus will be on the application of membrane processes for (i) desalination (ii) water and wastewater treatment (iii) biomedical and food processing as well as (iv) gas purification. In order to probe the key fundamental concepts and operational principle in depth, the course will focus primarily on five different membrane separation processes, namely (i) microfiltration, (ii) ultrafiltration, (iii) nanofiltration, (iv) reverse osmosis and (v) gas separation would be pursued in detail. Perspective on separation process down to molecular level will be given to familiarize the students with the fundamental forces involved for these membrane processes. Later, a more conventional engineering approach driven by both empirical calculation and also first-principle mathematical modelling would be used to develop design rule for the membrane processes involved. |

|

|

|

| EKC 462/3 Advanced Control Systems for Industrial Processes | |

| Synopsis: |

This course will introduce the concepts of advanced control strategies, multi-loop and multi-variable control as well as model-based control strategies. This course will also introduce the control concepts for systems with large dead time. |

|

|

|

| EKC 464/3 Biorefinery Engineering | |

| Synopsis: |

This course covers fundamentals of biorefinery concept, resources, characteristic and energy content of biomass/feedstocks, pretreatment techniques for biomass, process reaction, synthesis and conversion technologies in biorefinery, separation and purification technologies in biorefinery and biorefinery system. |

| EKC 463/3 Advanced Process Safety Engineering | |

| Synopsis: |

This course covers industrial accident analysis, human factor principle and analysis, system safety engineering, computer aided modeling of major hazards. It also covers advanced risk assessment and application of Inherent Safer concept in designing a chemical plant. |

| EKC 475/3 Wastewater Treatment Engineering | |

| Synopsis: |

This course contains physical, chemical, advanced and biological treatment of wastewater including design, operation, analysis and troubleshooting of treatment plant. In addition, it also deals with treatment, reuse and disposal of solids and bio-solids produced during wastewater treatment processes. |

| EKC 483/3 Petroleum and Gas Processing Engineering | |

| Synopsis: |

The students will be able to understand the operations of downstream processing units of petroleum refining plant and natural gas treating processes. The student will learn about crude oil and petroleum products properties and specifications. The student will gain knowledge about the operation of petroleum refinery and natural gas processing units. |